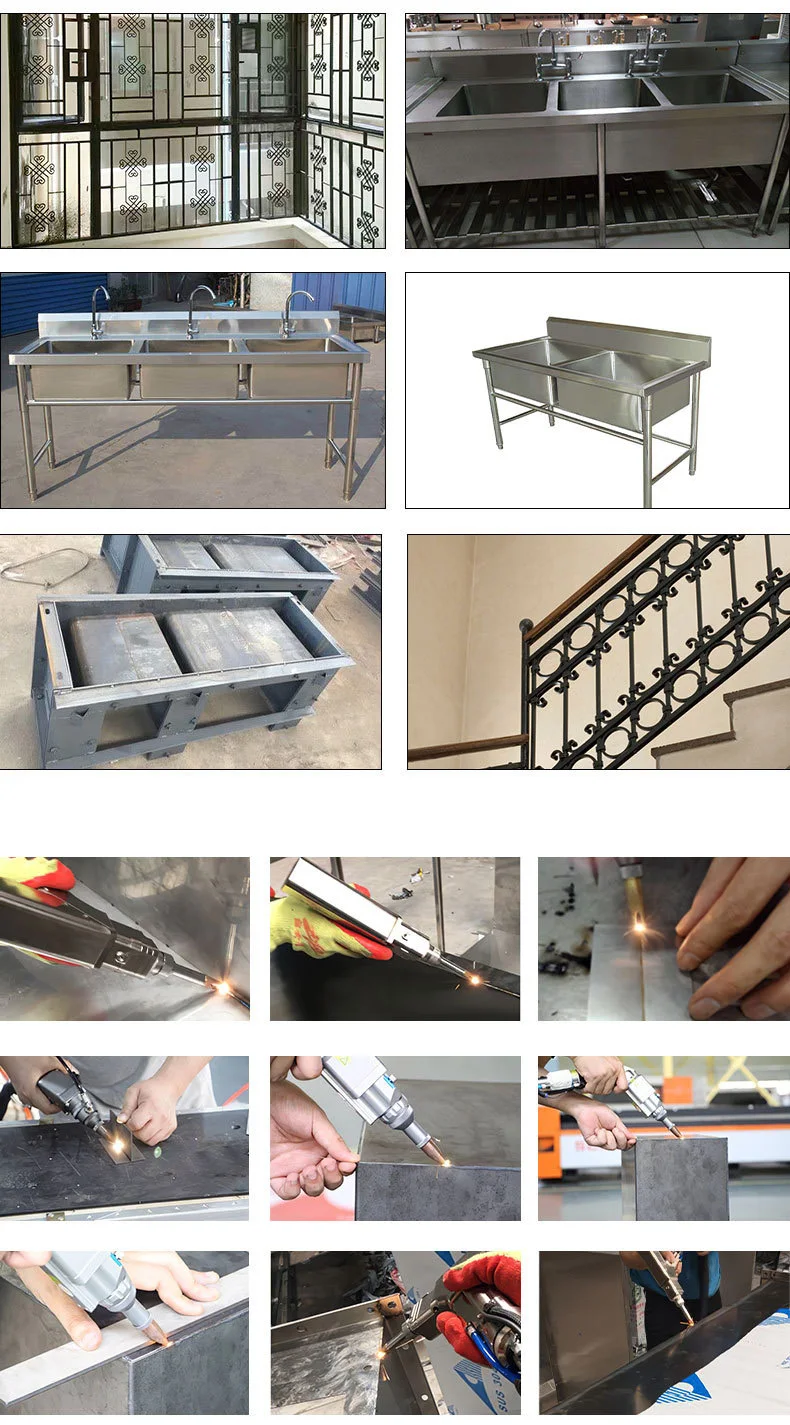

●VERSATILE: Wide range of materials – up to 1/4 in. (6.35 mm)

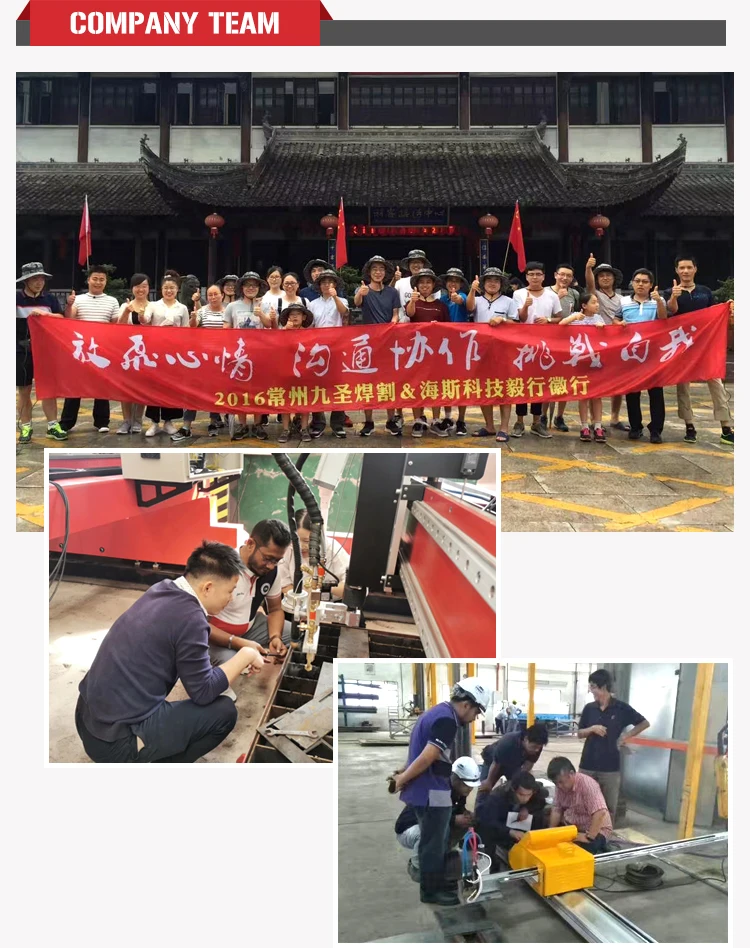

●EASY: Optimized presets reduce learning curve

●CONSISTENT: High-quality, repeatable results

●FLEXIBLE: Simple and challenging applications

●PRODUCTIVE: Pre- and post-weld cleaning capability