QUALITY MANAGEMENT SYSTEM

Meisar CNC is one of the biggest suppliers among cutting equipment in east China. Company mainly engage in CNC laser cutting machine, CNC plasma cutting machine, CNC Pipe/Tube cutting machine, etc. Meisar CNC has 14 years history, serving more than 80 countries and regions.

Meisar CNC has strict quality control system and quality management team. Strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer’s requirements.

Incoming Inspection

For every part of the machine, Meisar CNC is strictly control the quality.

Not only require suppliers to provide quality inspection reports, but also strict quality monitoring will be carried out when the parts are in the factory.

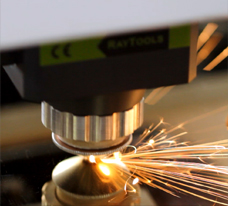

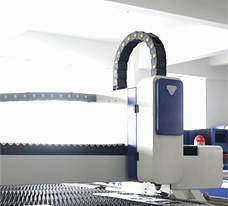

Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Meisar CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.

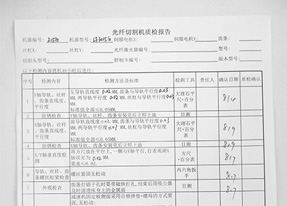

Pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance, stability, fit, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, To ensure that the final factory, the machine is in the best condition.