Good quality Thermal-Dynamics - Gantry CNC flame&plasma cutting machine – Meisar

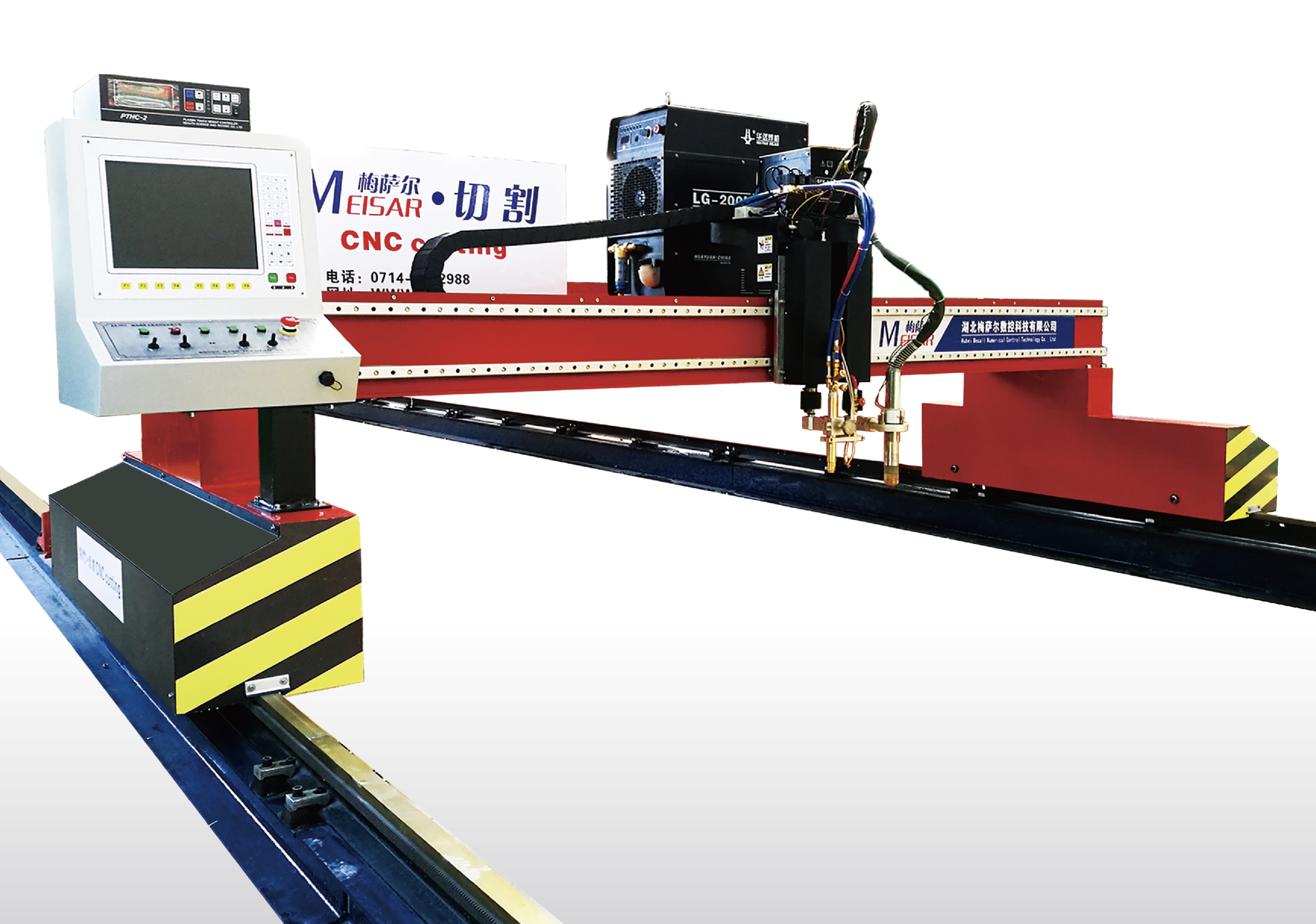

Good quality Thermal-Dynamics - Gantry CNC flame&plasma cutting machine – Meisar Detail:

Features

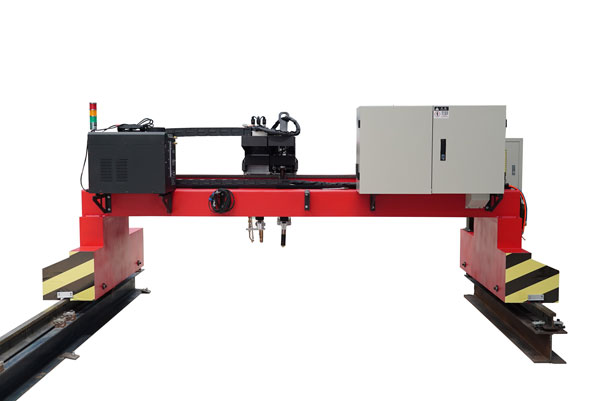

- The whole machine adopts the welded steel plate welded structure. The beam is cut by laser cutting and then welded together. The upper and lower sides of the beam are bent by 90 degrees with the steel plate, which can reduce the deformation and increase the rigidity.

- The beam hanging plate is welded with 20mm steel plate, and the whole surface is processed by gantry planer to reduce the deformation of the whole surface and improve the precision.

- After the whole machine is welded, firstly, the aging treatment is performed after stress aging, followed by the surface rust removal treatment. After the primer is applied, the surface is painted.

Technical parameter

| Model | MS-4B (4080) | MS-4B (5012) | MS-4B (6012) | MS-4B (7012) |

| Machine structure |

Laser cutting, steel plate welding structure with heat treatment |

|||

| Effective cutting range(X/Y) | 3000 x 6000mm | 4000 x 10000mm | 5000 x 10000mm | 6000 x 10000mm |

| Lateral rail spacing | 4000mm | 5000mm | 6000mm | 7000mm |

| Longitudinal guide length | 8000mm | 12000mm | 12000mm | 12000mm |

| The number of lifts |

Standard for the double moving lift device |

|||

| Input voltage |

AV-220V Single phase AV-220V |

|||

| input power |

About 2500W |

About 3000W |

||

| Running speed |

0-10000mm/min |

|||

| Cutting type |

1, plasma cutting (with plasma power) 2, flame cutting 3, flame + plasma cutting |

|||

| Torch lift |

≤160mm |

|||

| Operating accuracy |

0.2mm/m |

|||

| Flame cutting thickness |

Piercing thickness: 5-60mm Edge cutting thickness: 5-200mm |

|||

| Plasma cutting thickness |

According to the size of the plasma power supply |

|||

| Flame automatic Ignition device |

With flame automatic ignition device function |

|||

Customer use site

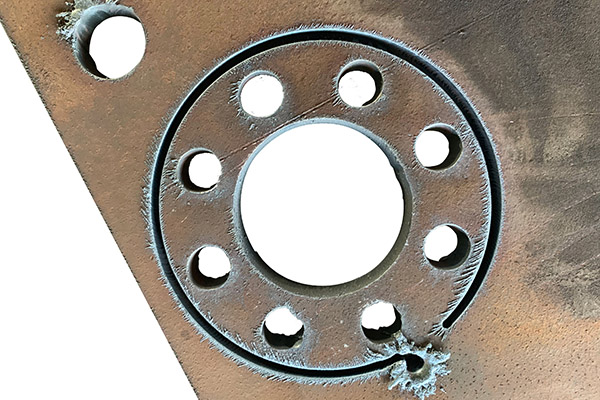

Cutting Sample

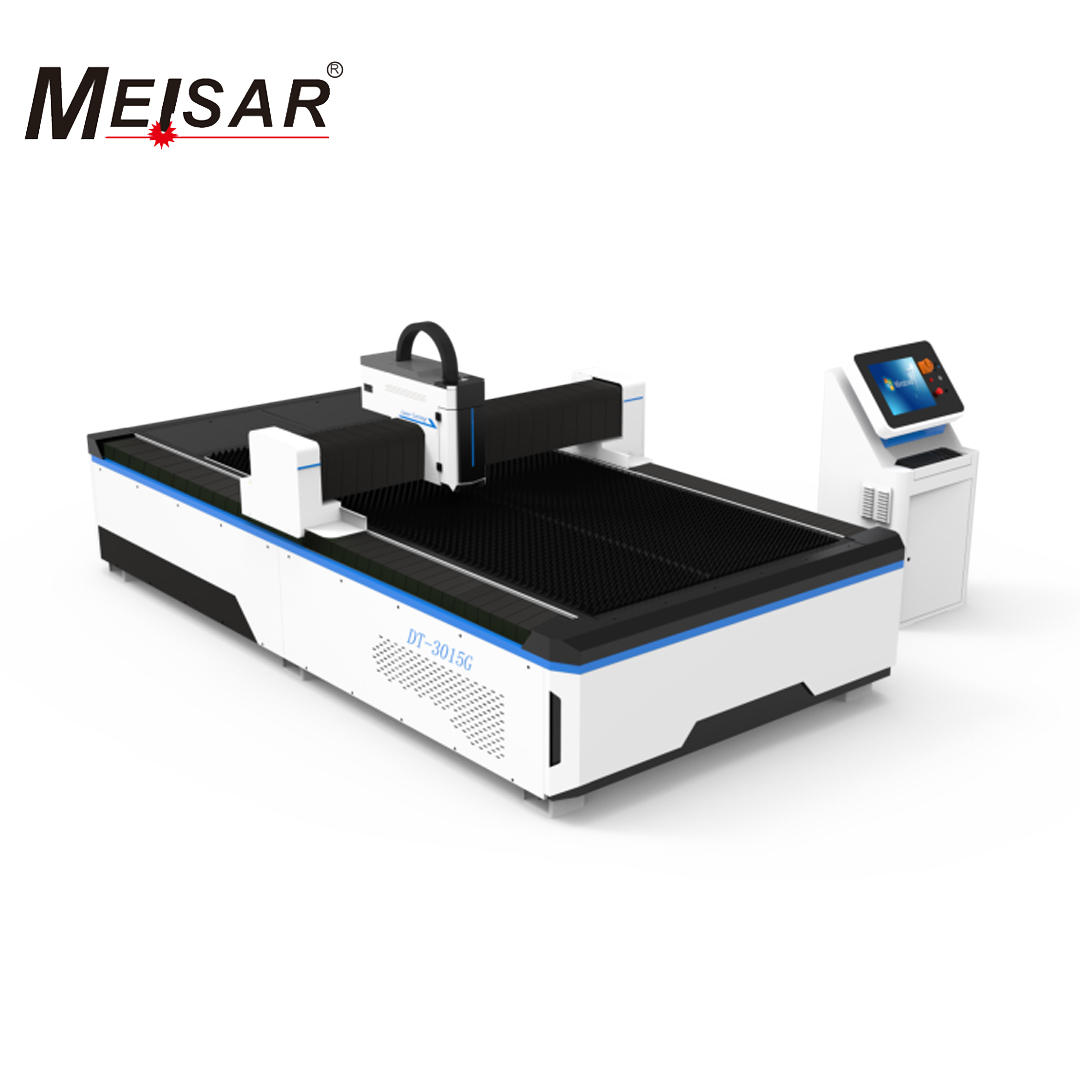

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

abide by the contract", conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for Good quality Thermal-Dynamics - Gantry CNC flame&plasma cutting machine – Meisar , The product will supply to all over the world, such as: Australia, Cairo, Palestine, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Write your message here and send it to us