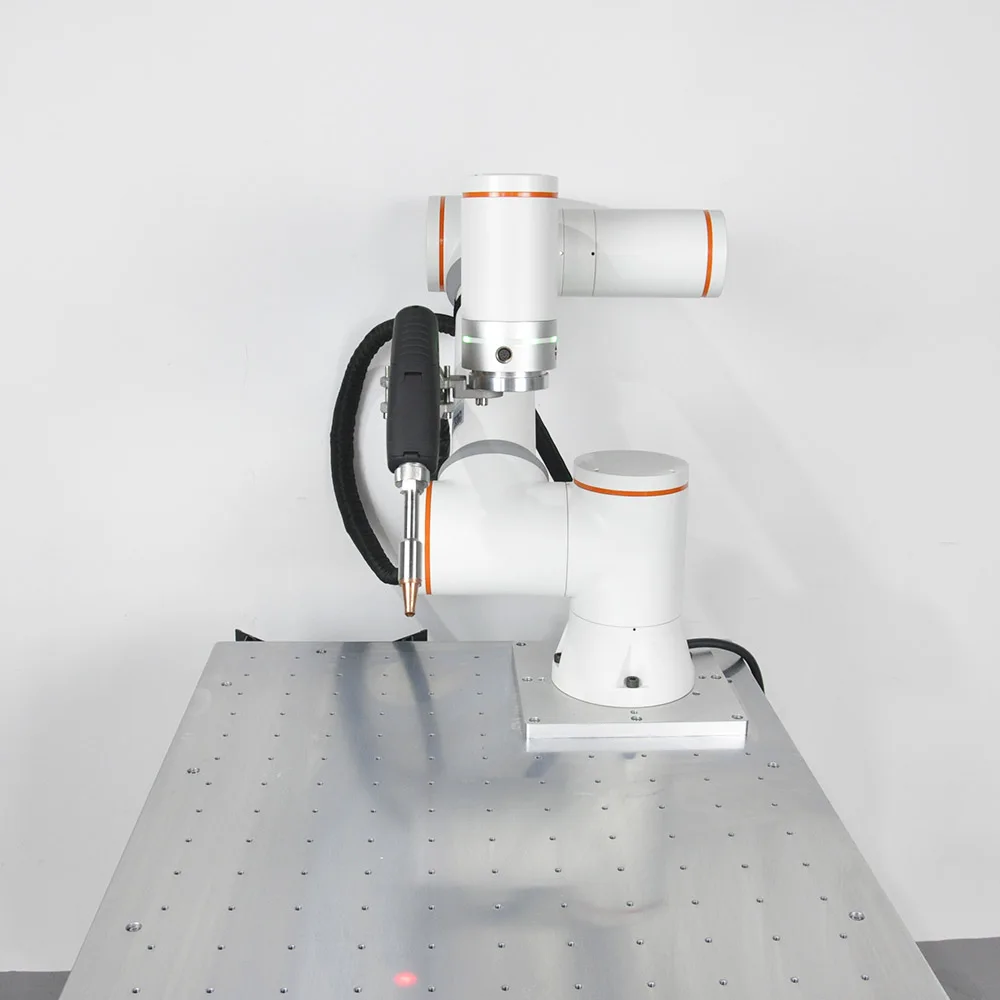

FR-Series Cobot

Collaborative robots will extend your time and space, liberate complex and inefficient repetition, and let you embrace a wider horizon.In the future, You will see FAIR EVERYWHERE.

With its emergence, it not only improves the effciency of human-machine collaboration, but also speeds up the automation process for more enterprises and frees floor space and lowers the cost of implementing robots for manufacturers.

With its emergence, it not only improves the effciency of human-machine collaboration, but also speeds up the automation process for more enterprises and frees floor space and lowers the cost of implementing robots for manufacturers.