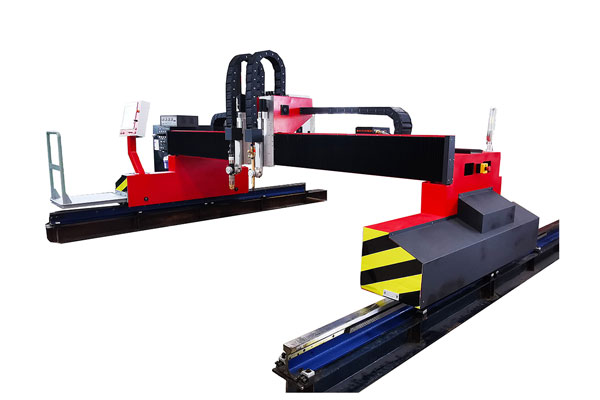

Best quality Sheet Metal Router Bits - CNC fine plasma cutting machine MS-4C – Meisar

Best quality Sheet Metal Router Bits - CNC fine plasma cutting machine MS-4C – Meisar Detail:

Technical parameter

| Model | MS-4C(4012) | MS-4C(4012) |

| Effective cutting range | 3000mm x 10000mm | 3000mm x 10000mm |

| CNC system | EXC880 | ICNCXT |

| Input voltage | AV-220VSingle phase AV-220V | AV-220V Single phase AV-220V |

| input power | 3200W | 3200W |

| Running speed | 0-15000mm/min | 0-15000mm/min |

| Torch lift | ≤160mm | ≤160mm |

| Operating accuracy | 0.2mm/m | 0.2mm/m |

| Longitudinal track/rack | Fine grinding 55KG/M track / fine grinding helical tooth | |

| Plasma cutting thickness | According to the size of the plasma power supply | |

Features

The perfect mechanical structure, ultra-high standard processing technology and strict quality management have created the highest level of plasma cutting machine.

The CNC fine plasma cutting machine is the finest plasma power supply with the most high-precision CNC machine tool and the most advanced technology in the world. It not only has the characteristics of the current ordinary plasma cutting machine, but also has the following characteristics:

1/Surface cutting roughness Ra ≤ 13 Cutting verticality ≤ 2 degrees, surface cutting quality reaches the lower limit of laser cutting quality.

2/Cutting size accuracy is more than double that of ordinary plasma.

3/The slit width is about 1/2 of that of ordinary plasma.

4/ Cutting medium plate speed is higher than laser and ordinary plasma.

5 / electrode / nozzle life, far more than ordinary plasma, about 5 times more than ordinary plasma.

6/ Equipment investment cost and operating cost are only 1/3-1/9 of laser laser.

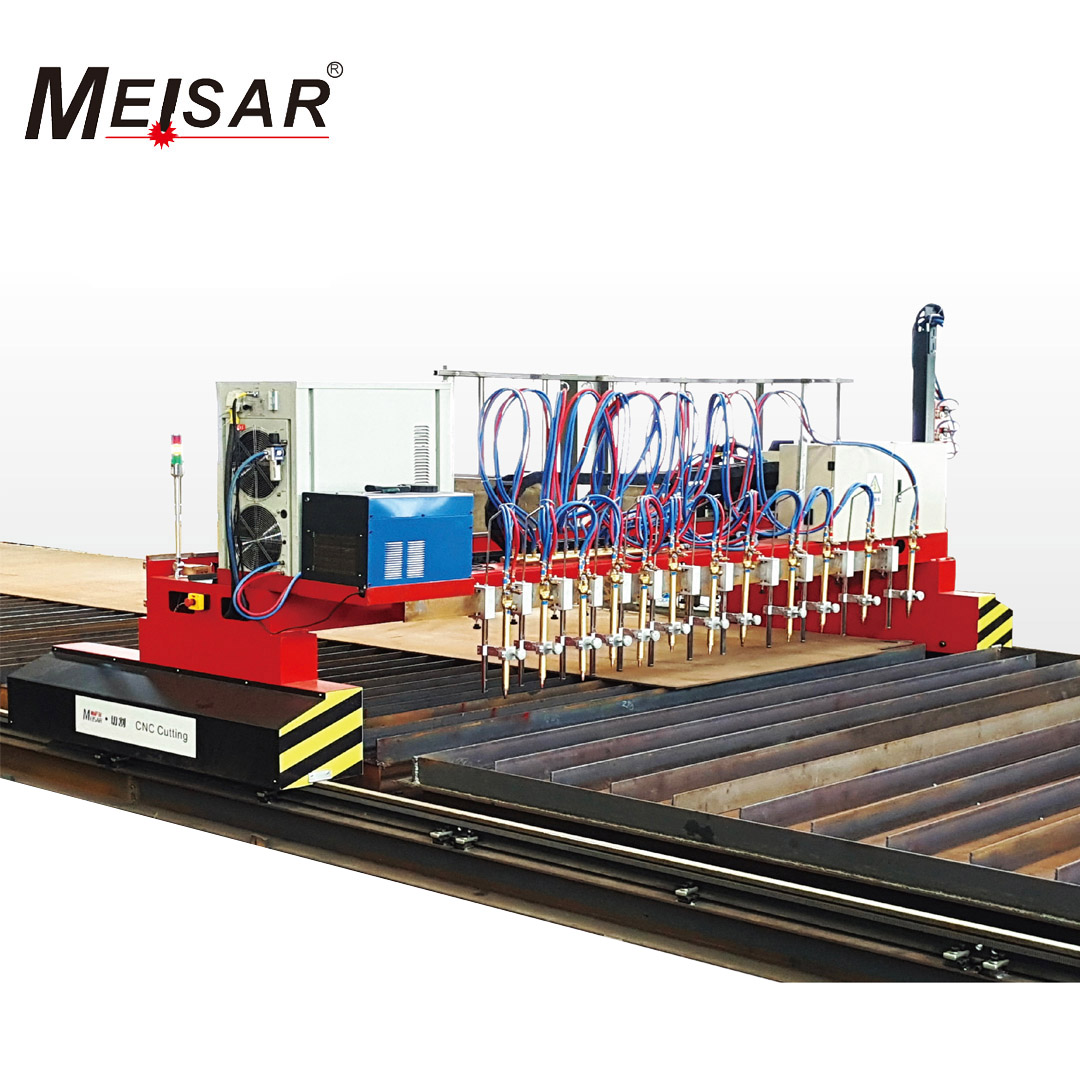

Customer use site

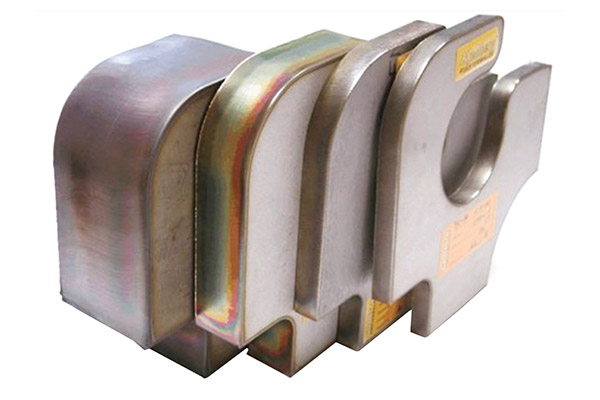

Cutting Sample

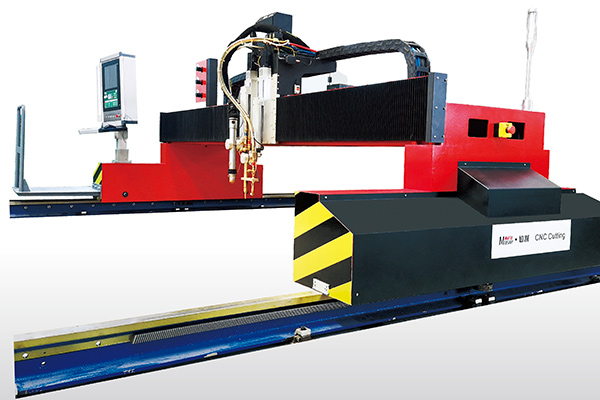

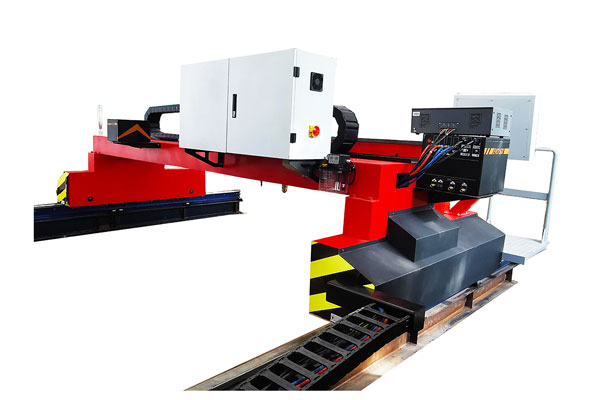

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Best quality Sheet Metal Router Bits - CNC fine plasma cutting machine MS-4C – Meisar , The product will supply to all over the world, such as: Lesotho, Bulgaria, San Diego, In order to meet the increasing requirement of customers both home and aboard, we will keep carrying forward the enterprise spirit of "Quality, Creativity, Efficiency and Credit" and strive to top the current trend and lead fashion. We warmly welcome you to visit our company and make cooperation.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.